Introduction

I had been building and flying what I thought were real Eddy style kite designs for a few years. I had made a number, mostly of wooden dowels and simple materials such as drafting paper and gift wrap, and always a dihedral on the cross sticks. I had even made a ripstop nylon and fiberglass tube version, again with the dihedral

Then I read a Drachen Journal article and one called

Diamonds in the Sky on William Abner Eddy. My ideas of the eddy kite took a full 180 degree turn and things have not been the same since. What followed was an intensive quest into the life of Eddy, the times, and his kite.

How I Got Here From There

With the help of my kiting friend and kite historian, Bob White, a three month investigation into William Abner Eddy led to a discovery of some neat and surprising facts and details. I read everything I could find on Eddy and found out details that made his invention possible.

I believe the key to his success was that his access to worldwide information. Working for the New York Herald, did have its advantages. Even in the mid 1800’s, being able to read about and see things that were happening around the world was very important.

Eddy was, in his younger days, a kiting enthusiast. Like most kids of the time, he flew the popular kite designs and also made a lot of his kites. That spark from his youth certainly helped promote his later endeavors.

When confronted with a need to lift scientific instruments and cameras, Eddy realized that a train of kites was necessary. Trains of kites with tails on them led to tangling and unsafe flights. There then became a niche to fill, because there was the need of a better solution. That, above all, led Eddy to work through the problem and come up with a viable solution. The tailless Eddy kite.

That is where I took up the torch and brought his success into the 21st century. Not too many people flew Eddy kites due to the perception that “it’s just a toy.” I knew that nobody flew the Eddy style trains any more. Thus a “need” was created and I found a small niche in the kiting world that was just hankering for a solution! 😉

The Design

The one great thing about people like William Eddy and the times he lived in was that they loved to patent their designs. This created official precise documents that became part of the record to be available to people like myself a century down the road.

Eddy’s patent No. 646,375 dated March 27, 1900 became the basis for my modern versions of his original design. Even this was a bit tricky seeing as an Eddy kite could be made in an infinite number of sizes. The drawings and descriptions were vague on exact dimensions and details. Reading other people’s accounts didn’t always give accurate information either. So with a bit of detective work, reading between the lines and some cross referencing, I finalized the exact shape I was going to use.

The Shape

According to the patent there were a few things that distinguished the Eddy kite from others. They are…

- The lengths of the spine and cross spar are equal.

- There is a perimeter line going around the kite on which the sail is mounted.

- The sail is mounted to the frame by means of rings at the four corners.

- The sail is “loose fitting” in order to create pockets to catch the wind and create a “keel” along the spine.

- The sail along the spine is tight from nose to tail unlike being loose along the cross spars.

- The cross spar is attached at a point approx. 20% down from the nose.

- Last but not least the kite is bowed by means of a bow line from wing tip to wing tip.

These are the facts I took into consideration when making up my kites. I took the following passage from an account of a train and used it as the basis of the train I made.

Writing about the lift on August 4, 1894 Eddy writes:

“On August 4 the highest point reached with a thermograph, made by Richard Brothers, Paris, remodeled and lightened by the use of aluminum, by Mr. S. P. Fergusson, of the Observatory, was 2,040 feet above sea level, or 1,400 feet above the hill.”

“It brought down a record of 6 degrees colder than the earth’s surface. The instrument was supported at the intersection of three tandem Malay kites, one seven and two four feet in diameter, and was projected upward with the lifting power on the main kite line below of one nine foot and two six foot kites. So far as the writer knows, the nine foot kite, made by Willard Fergusson, was the largest Malay kite ever built. The total maximum pull for the six kites was 48 pounds, by spring balance, and the minimum was 30 pounds.”

This description led to my train configuration.

But First a Prototype

I figured the best way to proceed was to make a “test” kite to see if I was on the right track. I built my kite five feet tall using materials at hand. First the frame and perimeter lines were constructed and linked together. Measurements were taken for the sail which was then created from ¾ oz ripstop nylon. The perimeter lines were threaded through the sails edge seams and mounted to the frame. A bridle was attached at the appropriate points and a test flight ensued.

Success

It was a cold, damp January day with winds at around 6 Km/hr when I took my prototype out to the flying field for a test run. After a couple bridle adjustments to get the right angle of attack, my five foot Eddy glued itself to a spot in the sky. It didn’t waver or dance but just “stuck” there. My ear to ear grin was just as stuck on my face. The pull was noticeable and when the wind slowed to a whisper it floated gently to the snow. To say I was impressed was an understatement!

It was a cold, damp January day with winds at around 6 Km/hr when I took my prototype out to the flying field for a test run. After a couple bridle adjustments to get the right angle of attack, my five foot Eddy glued itself to a spot in the sky. It didn’t waver or dance but just “stuck” there. My ear to ear grin was just as stuck on my face. The pull was noticeable and when the wind slowed to a whisper it floated gently to the snow. To say I was impressed was an understatement!

Onwards and Upwards

With this test flight under my belt and a ton of confidence, it was time to get working on the train. I looked at all the materials available to me and determined which was suitable for each of the 4 sizes. I talked to a kiting friend and master builder, Steve Finch, to see if he could make me some custom Tee’s to use at the cross points in the frames. We agreed on sizes and materials and then I got to work on the drawings.

With this test flight under my belt and a ton of confidence, it was time to get working on the train. I looked at all the materials available to me and determined which was suitable for each of the 4 sizes. I talked to a kiting friend and master builder, Steve Finch, to see if he could make me some custom Tee’s to use at the cross points in the frames. We agreed on sizes and materials and then I got to work on the drawings.

Eddy himself documented proportions of the spar cross points from 18 to 20 percent. I split the difference and used 19 percent as the spar cross point position on my kites. To make the sail the right dimensions, I used the height as the exact distance of the perimeter lines at the rings and for the width added 7%. This I took from an Italian design for making “original” style Eddy’s. The patent never alluded to how much bigger to make the width of the sail.

The materials came in and the building started. Unlike just about every other kite I have made, The Eddy kites were made pretty much in reverse. In order to get the right dimensions for the sails, I had to construct the frames complete with the perimeter lines first.

I started with the 9 footer, seeing as I now had the FL505 epoxy tubes, arrow nocks, aluminum rings, solid core Dacron and a custom aluminum Tee. I have never made such a big Eddy style kite before and the size of the 9 footer was awesome. Plus the only way I could set it in my home was with the trailing edge on the floor which left the wingtip about 3” from the ceiling! The sail was made to match the frame and attached. I used 190 lb. test solid core Dacron for both the perimeter line, the bridle and bow line. It worked quite satisfactorily. A Stainless steel ring larks headed to the bridle, complete with a short tow loop finished off the assembly. Then off to the flying field for a test flight.

I started with the 9 footer, seeing as I now had the FL505 epoxy tubes, arrow nocks, aluminum rings, solid core Dacron and a custom aluminum Tee. I have never made such a big Eddy style kite before and the size of the 9 footer was awesome. Plus the only way I could set it in my home was with the trailing edge on the floor which left the wingtip about 3” from the ceiling! The sail was made to match the frame and attached. I used 190 lb. test solid core Dacron for both the perimeter line, the bridle and bow line. It worked quite satisfactorily. A Stainless steel ring larks headed to the bridle, complete with a short tow loop finished off the assembly. Then off to the flying field for a test flight.

This time the wind was gusty at around 20 Km/hr. The same thing as before, a few adjustments of the tow point and that big Eddy was purring like a kitten. It took the gusty winds amazingly well. Of course it moved around in the varying breeze but held its own and stayed very stable. It certainly had some pull. The pockets, created by the wind against the loose sail really grabbed the air, and when a sustained gust hit it, I had to hang on tight. What a rush!

The Rest of the Train

With the second Eddy kite up and running, it became an obsession to get the remaining 5 kites finished. The 7 footer used FL414 tubes, the two 6 footers used K75 tubes for the spines and C30 tubes for the spreaders. The two 4 footers used C30 tubes all round. I also had some 100 lb. test solid core Dacron line which I used on the smaller kites. The low stretch aspect of the solid core Dacron was the main factor in its use.

With the second Eddy kite up and running, it became an obsession to get the remaining 5 kites finished. The 7 footer used FL414 tubes, the two 6 footers used K75 tubes for the spines and C30 tubes for the spreaders. The two 4 footers used C30 tubes all round. I also had some 100 lb. test solid core Dacron line which I used on the smaller kites. The low stretch aspect of the solid core Dacron was the main factor in its use.

In late spring I had the kites completed and tested. Now I had to figure out how to make the train lines. Eddy never documented the lengths of the lead lines or the distances between kite attachment points. I had seen other references describing 300 feet between attachment points and another from years later talking about 2,000 feet. With a 1,000 foot height limit I had to scale down to something usable.

The Reel and Lines

Eddy flew his trains in a fashion you just don’t see much anymore. Each kite flies on its own “lead” line which allows it to fly independently of the others. This feature allowed each kite to find its “space” in the sky while still adding to the collective lift of the train. It was quite a novel idea and a great way to deal with so many large kites. I learned early that in order to keep the kites from hitting each other, the distance between the lead line attachment points and the length of the lead lines had to be different. Because the total length of the main line could get WAY out of hand, I settled on 60 feet between attachment points and each lead line would be 40 feet to allow launching into nice air and avoiding kites tangling.

Eddy flew his trains in a fashion you just don’t see much anymore. Each kite flies on its own “lead” line which allows it to fly independently of the others. This feature allowed each kite to find its “space” in the sky while still adding to the collective lift of the train. It was quite a novel idea and a great way to deal with so many large kites. I learned early that in order to keep the kites from hitting each other, the distance between the lead line attachment points and the length of the lead lines had to be different. Because the total length of the main line could get WAY out of hand, I settled on 60 feet between attachment points and each lead line would be 40 feet to allow launching into nice air and avoiding kites tangling.

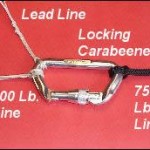

Now, I had to sort out how I would deal with all this line. It was still 300 feet between the top kite and the attachment point for the bottom kite. I divided the line into two parts. The top section had 5 kites attached to it with the attachment point of the bottom kite being also the point where it attached to the rest of the line. I use a locking carabineer to allow the attaching and detaching of the lines.

Now, I had to sort out how I would deal with all this line. It was still 300 feet between the top kite and the attachment point for the bottom kite. I divided the line into two parts. The top section had 5 kites attached to it with the attachment point of the bottom kite being also the point where it attached to the rest of the line. I use a locking carabineer to allow the attaching and detaching of the lines.

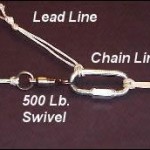

The lower section has is reeled on a custom made reel by my friend and expert machinist Steve Finch. Knowing that I would be launching and working with the train without support crews at times, a reel that could be locked in place and anchored to something solid was a necessity. I reeled on 300 feet of 750 lb. test polyester over nylon line to serve as the anchor section of the flying line. The next 120 feet of themain flying line is 500 lb. braided Dacron and the top 120 feet of line is 250 lb test Dacron over Kevlar.

Each lead line is 40 feet of the 250 lb. Dacron over Kevlar. Better to have line that won’t get cut. A 500 lb ball bearing swivel and metal chain connecting link is used to attach the upper two sections of main line. Stainless steel welded rings are larks headed to the main line at the remaining attachment points. That gives me a complete line set to fly this train and get it up in the sky with ease.

Each lead line is 40 feet of the 250 lb. Dacron over Kevlar. Better to have line that won’t get cut. A 500 lb ball bearing swivel and metal chain connecting link is used to attach the upper two sections of main line. Stainless steel welded rings are larks headed to the main line at the remaining attachment points. That gives me a complete line set to fly this train and get it up in the sky with ease.

First Flights

Let me tell you that getting six large kites in the air at the same time is NOT an easy feat the first time out! Especially if the wind isn’t totally cooperative. Using a bit of logic… just a wee bit… I thought that launching the top kite first and so on down the line would have been easy. The first kite went up nicely till the wind died off and it came back down before I could get the second one up. Finally the wind picked up I got the first two kites up and then the wind died as the third kite was being launched. On and on it went, giving a whole new meaning to the words “20 minute workout.” I eventually lofted the whole train up high enough to get some pictures before the wind shifted and died again. Oh, the trials and tribulations of being a kite flier!

The second time out worked much better. With a steadier wind, the train lifted off and gained some altitude and hung in there. I was able to make some fascinating observations. When Mr. Eddy made each kite fly independently, it was for good reason. Each kite was able to find its “space” in the sky. Boy, they sure did. I had great thoughts of a nice, neat lineup of kites but it isn’t so. Each kite was flying either to the right or left of the main line but only very occasionally did they line up. I found that very interesting. Also when the wind is “on,” the train has great pull. That is what Eddy himself experienced and I suspected. I was very pleased that the individual kites do all work together.

Another observation is that each kite has to be tuned to fly properly. Especially the two 4 footers. Those two will dance all over the place if the bridle and bowing is not set right. Mind you, they will fly nice and steady as individuals, but like to dance when added to the team. Interesting thing, that is.

The Big Event

OK, now it is the day of the Canal Days kite Festival in Port Colborne, Ontario where I am doing the “official” unveiling. I have had two test flights. Things seem fine and I am praying for a nice steady onshore wind at about 15 Km/hr. Low and behold I got my wish, highly unusual. Late in the afternoon as one of the last things to be presented, my Eddy Kite train lifts itself into the air and flies flawlessly. Bob White’s commentary over the loud speakers is music to my ears. I can’t stop grinning. I even get Bob over to fly it for a bit and the grin on his face says it all.

So, after its original flight of 111 years ago, a modern recreation of a kite train flown by William Eddy himself, rose into the sky again. What a moment in time.

Thank you,