Some time back, I published an overview of Line Laundry. You can see the details here. But in this report, I’m going to try and be a bit more technical.

Some time back, I published an overview of Line Laundry. You can see the details here. But in this report, I’m going to try and be a bit more technical.

I’m asked from time to time about line laundry. How much can you fly? What works best? What looks best?? And the answer is always – it depends. So let’s talk about that and at least try and clarify some of the questions, if not answer them.

First of all, what is “laundry”? Anything that hangs on a line can be called laundry. That includes flat tails and streamers, tubes, line art, wind socks, and inflatable animal shapes. At some point, the line between kites and laundry can actually blur as we use lifters more and more, and fly creations that are less able to fly on their own.

I suppose you could argue that anything connected only to the flying line of another kite is laundry, and that a piece with its own flying line, even if being supported, is a kite. But get three kiters together over beer and you’ll get four opinions on that! Suffice it to say that I don’t really care about technical definitions as long as the thing goes up in the air and makes people smile. Fair enough??

So what affects your ability to lift laundry? The first consideration is the lifter. Different style kites lift more efficiently than others. For example, a DC will lift more than a standard Delta. A Parafoil will lift more per square foot than a FlowForm. And a larger kite will lift more than a smaller one, of course.

So what affects your ability to lift laundry? The first consideration is the lifter. Different style kites lift more efficiently than others. For example, a DC will lift more than a standard Delta. A Parafoil will lift more per square foot than a FlowForm. And a larger kite will lift more than a smaller one, of course.

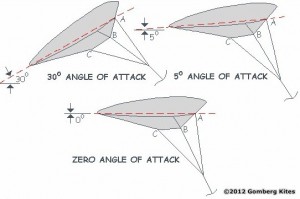

Tuning is also important. Many kite designs can be adjusted to generate more pull or lift. What else besides the kite itself? Wind. How strong is the wind? How constant is the wind? Is it dry wind or damp wind? Are you at sea level or higher altitude? Are direction changes expected? All of these factors and more impact your ability to lift.

Some years back, a customer purchased a Pilot 50 for lifting equipment and was kind enough to share their test results. But those results varied. Even at a wind speed of 12 mph, the pounds of lift varied from 18 to 32 pounds. The average lift was 27.75 pounds at 13 mph of wind. That came to .56 pounds of lift per square foot of kite lifting surface. But those numbers don’t mean much since the range was 10-21 miles of wind and results of 18 to 38 pounds of lift. Little help.

You also need to factor in the size, shape, and drag of whatever you want to lift. Sheer bulk is one measure. Ten pounds of fabric is going to need more lift than 5 pounds. But I’ve seen plenty of larger laundry begin to lift on its own in the right circumstances. And I won’t soon forget standing by a 200 foot SpinSock after the lifter came down and the sock kept “flying”.

You also need to factor in the size, shape, and drag of whatever you want to lift. Sheer bulk is one measure. Ten pounds of fabric is going to need more lift than 5 pounds. But I’ve seen plenty of larger laundry begin to lift on its own in the right circumstances. And I won’t soon forget standing by a 200 foot SpinSock after the lifter came down and the sock kept “flying”.

So. If there are no measurements, no standards, and no guidelines, what is a kiter to do until they gain a bit of experience and intuition? The best answer is to guess.

If laundry seems too big for the kite, it probably is. And if it seems too small, the kite will lift it but things probably won’t look right. Proportion is important!!! So that is a good standard rule to start with. Don’t put a 20 foot tube behind a 90 foot lifter. Don’t try and pull up a 90 foot sock with a 9 foot Delta. Make sense??

Second bit of advice? Don’t worry about lifting everything up high. A large piece of laundry is going to hang closer to the ground. So the line will go from the anchor to the laundry and then from the laundry to the kite at different angles. And that usually isn’t a problem. Big socks are more fun closer to the ground. Well, as long as you can keep kids out of the tails, they are…

Second bit of advice? Don’t worry about lifting everything up high. A large piece of laundry is going to hang closer to the ground. So the line will go from the anchor to the laundry and then from the laundry to the kite at different angles. And that usually isn’t a problem. Big socks are more fun closer to the ground. Well, as long as you can keep kids out of the tails, they are…

Third piece of advice? Minimize hardware, knots, and swivels. Anything between the ground and the kite is another place something can go wrong. How often have we seen a 50 pound swivel on a 150 pound line? What’s going to break first?? If a piece doesn’t turn, it doesn’t need a swivel!

We connect laundry to the line with small carabiners. I’ve seen other people use loops of line, rings, and clips. I prefer anything that keeps the main flying line un-knotted.

And getting back to swivels, they almost always tend to be a problem. Swivels are designed to go in water where they are lubricated. But with kites, the swivels are left dry and jam up with dust, dirt, and sand. Ball-bearing swivels, like our Sampos work well for the money. The best swivels are sealed bearing, very smooth, and a significant expense.

And getting back to swivels, they almost always tend to be a problem. Swivels are designed to go in water where they are lubricated. But with kites, the swivels are left dry and jam up with dust, dirt, and sand. Ball-bearing swivels, like our Sampos work well for the money. The best swivels are sealed bearing, very smooth, and a significant expense.

What laundry approach works best? That’s really personal preference. I like to display stuff in threes. And I like pieces fairly close together. Colors? Check our Building Your Show essay for design ideas.

What laundry approach works best? That’s really personal preference. I like to display stuff in threes. And I like pieces fairly close together. Colors? Check our Building Your Show essay for design ideas.

For larger animal shapes, I’ve begun attaching them into the flying line like any other piece of laundry instead of giving them a separate line to the ground. Lock the tow-point to the flying line with a biner, and clip the lifter loop into the line so that it slides freely. In some cases, you can lock top and bottom and share the biner connections.

It would be interesting if there were more technical data on what we’re doing. But fliers usually like to experiment and learn as they go. So would you read the tables if I had them??

Over time, a kiter will begin to intuitively recognize what will work. The learning curve is not steep. But it can be frustrating. So hang in there (pun intended.) The important thing is to be having fun!

David Gomberg