-

Posts

63 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Chook

-

Very sad and a good reminder to be as safe as possible at all times.

-

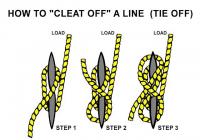

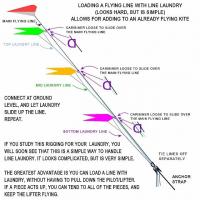

Yeh a climbing "figure 8" is used with the rope doing a 180 degree bend round the centre with 10mm thick dynamic rope. So smaller line doesn't work at all well. (I use the small end towards the pilot kite and give it an additional wrap through the big loop. I only use the 8 on my pilot kite.) I then anchor it to my vehicle and using plastic boat mooring cleats I can adjust my kites/laundry by running them up the main lifter line. My main lifter/pilot kite is 12m2. (130 square feet) By leaving a wrap on the cleat I can adjust the pilot kites height very safely in our sometimes strong sea breezes towards the end of the day. The 50mm grey webbing I use to attach to the towbar of my 4WD. The red roll of webbing on the top one is for tying round logs/ trees or fence posts. The webbing is 25mm with 6mm aluminium bolted between it. Sorry I cant find the original website I got the idea from. I use this to walk the laundry down, lowest first and then I can easily retrieved the lifter the same way by walking across the wind window as I walk it down to depower it.

-

You make the ground recoveries look so easy!

-

Best wishes and keep safe fella.

-

I work Monday to Wednesday at the local Agricultural College (Teaching building construction and Maintenance) On my days off I work from home from 8.00am to 12 knots...........to go power kiting in my buggy or land sailing. My local "Pink Lake" I use is only 2 kilometers away.

-

I just use little pig tails so I can remove the lines easily on all my kites. Particularly on my power kite lines when I'm wearing gloves it makes it so simple to do. Short bits of 150 lb dyneema fishing line with a simple overhand knot, sealed with a cigarette lighter and larks headed on.

-

After the first fly of my then new B Series Rev, I was devastated to find it had badly marred the sail where the vertical rods had rubbed. Running a finger nail down the rods there were super sharp "saw tooths". I went home and sanded all my rods with fine wet and dry sandpaper (done wet) to totally remove all the saw tooths. (Where they are wrapped with tape to cure) I then resprayed them with a rattle can of quality clear coat. I have now done all my rod sets, as I didn't realize they were all really rough and doing damage. The royal blue panels on the B Series had high lighted the wear straight off. I will say the Crystal T2 rods in my 2 Freilein quads, are already silky smooth right out of the bag.

-

As "SparkieRob" said, our wall- plugs are parallel and there is no way they could pull out once the screw is added. It's tough enough to hammer them into the handle as they are that firm. I do grind a taper onto the opposite end and drive this end into the handle first, to leave a perfectly rounded top just a whisker proud of the stainless tube, so there is no chance it will wear the leaders.

-

Yeh I agree Wayne. With the raw-plug and screw modification the attachment point is so close to the end. It's only inhibited by the exit point of plastic cap.

-

The pin idea sounds great but you would need to have a shoulder on the bead for a press fit to retain it somehow? If the pin was alloy (I'm thinking alloy TIG welding rod) it could be gently peened over to mushroom it on the ends. Or maybe if you added an internal "plastic tube?" bushing to be a press fit over pin it would add to its internal security. All my stainless handles have the raw-plug treatment (90 degree exit through the cap) but as mentioned I do get an occasional snag on the brake line. Even with my full alloy snag-less handles I can manage it. Just my dumb thumbs I reckon.

-

Running the line lengthwise through each handle? I had trouble with my carbon handles keeping the internal line taut as it always develops play/slop in between the knots and is a bugger to correct.

-

Yeh I use the glove hitch as shown above with good results. on my 4D. A slight change to the clove hitch is the "Constrictor Knot" if you don't ever want a rope/cord to ever loosen once tightened. I use this knot a lot for lashing parts together. Also the top of my power kite handles. (using a single piece as the leaders on both sides and the strop combined). Really the only way to undo it once it's had pressure applied to it is...........

-

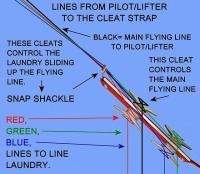

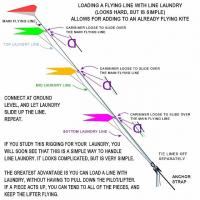

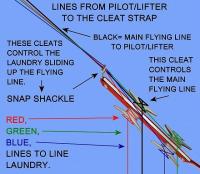

The original website seems to no longer exist unfortunately, by Barry Ogletree. (Whatakite) These are the only diagrams I can find that I saved to use as a base for my setup some time ago. Gives you some idea of the build.

-

Yeh to achor my display kites, I remove my tow bar and use the cross retaining pin to anchor my kites. Great if the wind changes direction as I can just reverse the car round. I pass my line doubled up through the figure of eight back round it like a mountain climber would do to decend, then down to a bottom cleat. I just use the figure of eight reversed as the kite line is much smaller in diameter than dynamic climbing rope it's designed for. The grey webbing goes into the tow hitch receiver and retained by the original pin. After setting my main lifter kite I can then send my laundry up fully controlled and tie off round the cleats to adjust them independently. (I cant find the original web site that this setup was detailed on and I copied it from. ) The top setup is for using a tree (see the extra 2800lb webbing retained by the elastic band by the roll of 1000lb line) I can easily adjust for more height while powered up if needed with my 26mtr Occy. I use 2200lb line on her as we get pretty strong sea breezes that can catch me out if they suddenly gust through.

-

I use 1000lb line on my 50' as it's a nice thickness and not so hard on my gloves, just because that is what I have. 500lb "may do it" as mentioned above. They are great lifters with good pull. I tie it to my 4 wheel drive on a grass paddock as it's easy to do. To get enough wind to launch it, I really think you are in trouble with only 150lbs. My little 26' Occys snap the lines that come with it in any sort of breeze and needed replacement. Yeh I put a loop "pigtail" on mine and larks head to it as they do up so tight and I didn't want a carabineer flapping around while retrieving it. (walking it down with a strap with a pulley on the end) 50' Occy

-

I started out with a 3.8m2 Peter Lynn Reactor and got reefed around learning by myself, but gradually worked my way up in stronger winds over time in my home made buggy. Yeh had the problem of stretching power lines on fixed bridal kites with lower poundage lines. Used Peter Lynn "Vapors" for years. 6.5m2 Vapor. 13.4 Vapor It's the small kites that spank you in wild winds. So be careful. Since going down the depower road (with thicker/stronger lines) it's the complete opposite with lines shrinking over time. Particularly the centre power lines. Up to 100mm shrinkage over time. I use pigtails to trim when needed. I haven't had any problems with my Ozone R1 power kites as I'm buggying and hotwired. (Kite is pulling on the buggys side rails) and I'm 250lbs. But others are reporting bridal shrinkage as well over time. 18m2 kite in 3 knots of wind equals 40kmh cruising along the beach. Or to up the pace to 93.4kmh a 7m2 Ozone R1and a Sysmic S2 buggy on Midi XL's. I love any time out with a kite!!!!

-

Does this help? It got me sorted out. https://kitelife.com/kl-archive/reviews/review-dual-line/issue-53-silver-fox-2-5-std-by-flying-wings/

-

Great job there. Certainly more patience than I've got. Mind you, I don't have a single day in the year that I cant go outside and work. There is a bit more ripstop there than a normal sail, by adding the double sided tape stitch lines, what is your final weight compared to your other kites? Does it really add that much to it? Keep em coming.

-

Gee that minimises the amount of sewing required. Love it!!!!

-

Is that a white sail that's been printed? Looks fantastic!!!!

-

I used a Plain Bugle head drywall screw from my local hardware store. The rounded head works a treat.

-

Totally agree!!!!! Great advice. Reckon they are punched not drilled when manufactured they are so internally jagged. Cut the hog clips and discard. Warm the caps in hot water and you can stretch them easily to get the leaders through one hole when reassembling them.

-

Hi Melissa. I did a similar thing to all my handles as the video shows and they work really well. I used a blue "8mm star plug" that's available in Australia and they are a perfect fit tap fit inside the stainless tube. Fit them backwards and leave them a little proud above the stainless tube and the rounded edge protects the leaders. I also bough a 13" pair of alloy anodised "snagless handles" (thinking they would be much lighter for when I travel by plane) and they were only 10grams less in weight than my modified standard rev ones, due to them being made from solid aluminium round bar. I also found these to wear at the point they exit the handle with a lot of use. Where as the modded standard rev handles don't as the cap supports/protects the leaders.. Carbon ones are really light, but I just don't click with them. Too light for my taste. A few drops of "Sewers aid" sewing lubricant run over your lines with a small bit of rag does the job and doesn't collect sand when dry. I still use my original set of lines when flying from dirty, gritty surfaces. They are trashed and very fuzzy but the oil stops them squeaking with lots of wraps. It's just pure silicon oil. (Kevin Sanders "Kaos" put me onto silicon oil and I bought a 1 litre bottle for Aus $34.00.) I use a lot of silicon oil for sewing windsurfing sails. It keeps the needle cool and the adhesive off the double sided tape doesn't collect on the needle.

-

Yesterday (first sunny day with steady wind for ages) I had my 85 foot Octopus lifting a giant squid and jellyfish. A lady who had driven down the dead end street to my Dads 20 acre block, said they had seen my display from 10 miles out of town and her little girls wouldn't let her drive by into town without a closer look. Got a lot of great compliments from cars that drove down and parked so the kids could watch. Even got a little lad flying his own kite he bought with him after I put it together properly for him. In the end had 8 Octopuses flying, as well as my laundry and only had to rescue my 8m2 ladybird out of a tree so a great day all round.

-

Yes your right................................2 tap washers and it's perfect!!!! Clever solution too matey!!!!

.thumb.jpg.54ee486fb066a0dad26655a8ad9debbe.jpg)

.thumb.jpg.0347f6215df2bc9ac24f6dce34bcd4b3.jpg)